By Justin Horne, Associate Director, Marketing & Communications

University of Washington Global Innovation Exchange

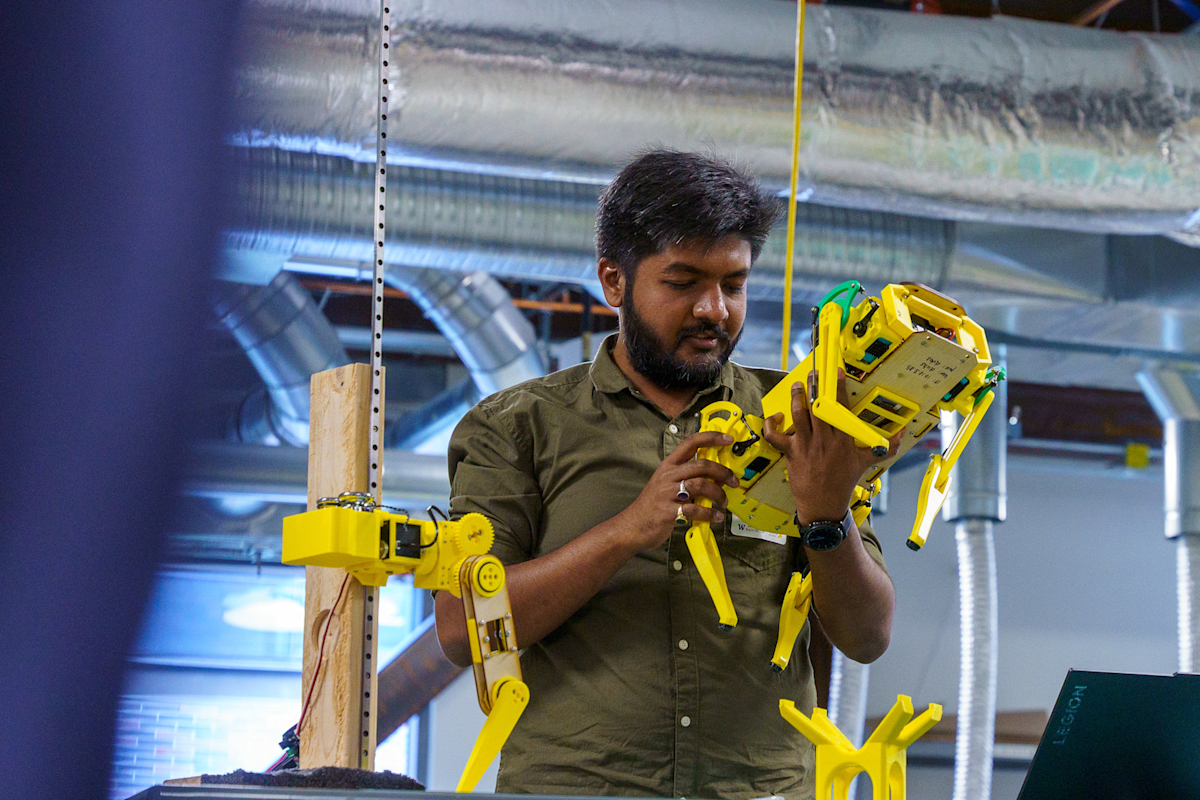

"I’m a builder. If I can’t make hardware that uses my software, I’m not satisfied,” Aayush Kumar muses while pointing out details on his 3D-printed quadruped robot.

Aayush, a graduate student in the robotics track of the MS in Technology Innovation (MSTI) program at the University of Washington’s Global Innovation Exchange, is advancing what’s possible with his quadruped robot project. His work combines hardware innovation, software optimization, and a vision for practical applications.

“It’s a quadruped robot, which is a four-legged robot, and each leg has three degrees of freedom,” Aayush explained. “I started this project in the summer using an open-source GitHub repository called Dingo.”

Aayush’s improvements began with refining the robot’s mechanical design. “The original design had joints directly connected to the servos, which caused too much stress on the connection point. I added long bearing-clamps to make it more robust, ensuring the forces didn’t concentrate on a single axle. That small change made a huge difference in the robot’s performance.”

Beyond hardware, Aayush dove deep into software optimization. “The majority of the work was actually on the software side,” he said. “There were lots of packages that I debugged, and I tweaked the packages that control the robot’s movement—parameters like how far it steps, how high it goes, and the speed at which it moves.”

But he didn’t even finish building this design before planning its successor; Aayush is developing a second-generation robot with even more ambitious goals and a refined design. “The new design is much lighter with lower loads. The legs can rotate 360 degrees without constraints.”

For Aayush, the project is more than a technical challenge—it’s an expression of his love for robotics. “I just love making robots. Since we’ve got a great facility here, it would be a shame not to take advantage of it. I made this robot in a week by using our 3D printers.”

One application he envisions for the quadruped robot is in the GIX Prototyping Labs. “I’m a member of the student crew, and there are lots of times that someone will come ask us where a tool is. We know where it is, but we must go show them. If we program where everything is, the robot can assist by walking the person to what they need.”

Looking ahead, Aayush is incorporating advanced technologies like 3D LiDAR and depth cameras to make his robot even smarter. “This design allows the robot to navigate challenging terrains, like construction sites,” he explained. “Unlike wheeled robots, it can handle uneven terrain, climb over beams, or work around obstacles to provide stakeholders with progress data.”

Aayush’s work showcases the blend of creativity, technical skill, and passion that defines robotics. “I’m pushing the limit to make my robots more flexible, dynamic, and reactive. I love making these robots do things you don’t think they can.”

Ready to work on projects like these? Learn more about the MS in Technology Innovation or apply to be a student.

Interested in sponsoring a project? GIX capstone projects offer corporate sponsors up to six months of access to international and interdisciplinary teams of graduate students in the University of Washington’s project-based Master of Science in Technology Innovation. Learn more here.

Back to News

Back to News